EGLIN AIR FORCE BASE, Fla. — A new high-speed camera system is revolutionizing the way munition detonation and fragmentation data is collected.

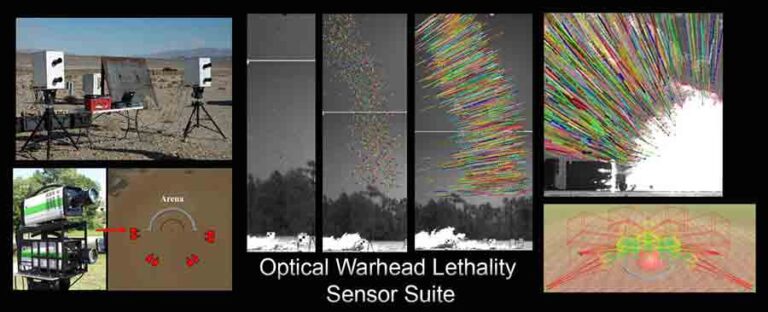

The portable system, known as the Optical Warhead Lethality Sensor Suite, captures imagery of fragmentation and debris fly-out following a warhead or munition detonation.

It takes that imagery and provides a three-dimensional fragment mapping and characterization such as mass, size and shape of the debris. The OWLSS does this by providing position, velocity vector and ballistic data for each fragment.

The system, available since earlier 2020, is owned and maintained here at the 96th Range Group, one of only three Air Force units to have an OWLSS. The system’s primary mission here is Arena testing, a static test where the warhead is exploded and the outward detonation effects is captured, measured and analyzed.

Before the OWLSS availability, to collect data during an arena test, large fiberboard panels were stacked surrounding the warhead. The panels would catch and collect the thrown debris when the munition was detonated.

Depending on the size of the munition, an average of 130 panels were set up manually for each test.

This type of setup, tear down, analysis and disposal of the panels is costly and adds many weeks to the testing and data analysis timeline. With OWLSS that monetary and time expenditure is cut dramatically which will enable faster and more agile testing, according to Kevin Stillwell, 96th RG.

“The OWLSS capability is a revolution in DOD arena testing methods for blast fragmentation data collection, whose full benefits are still being realized,” said Stillwell.

“As such, the use of this technology would not only serve to rapidly modernize data collection techniques but also directly benefit developers, testers, and the warfighter.”

Upon receiving the OWLSS, a combination of panels and camera were used at first. However, the Air Force Research Lab performed its first OWLSS-only Arena test earlier this year followed by another from an Air Force Life Cycle Management Center Program Office.

These tests used the OWLSS as the primary data-gathering system due to its monetary and labor savings over the fiberboard panels. However, it will always depend on mission requirements and specific test scenarios that will dictate how the data is gathered, according to Stillwell.

By Samuel King, Jr.